INTRODUCTION

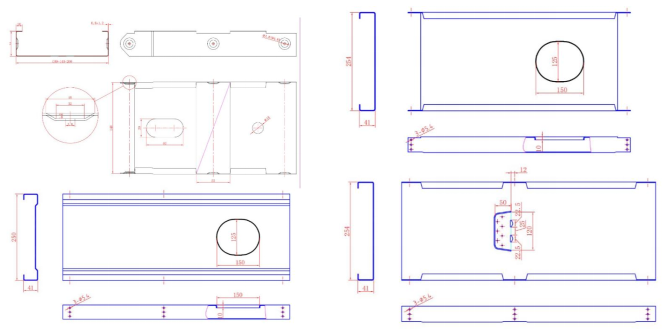

C2500 Light Steel Frame Roll Forming Machine(LGSF/LSF) is suitable for the profile drawings and material details:

Material: Dx51d, G350, G550, thickness:0.8 mm-2.0 mm;

Profile sizes :width 75mm -250mm; lip 10mm; flange: 41mm

If you have other requirement of the holes, we can desing it for you.

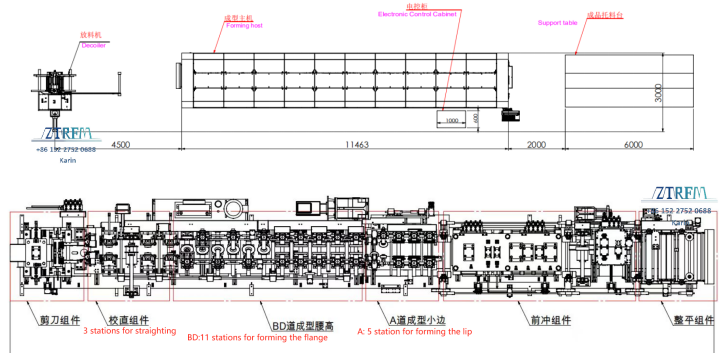

The layout and machine flow:

Equipment composition and detailed description

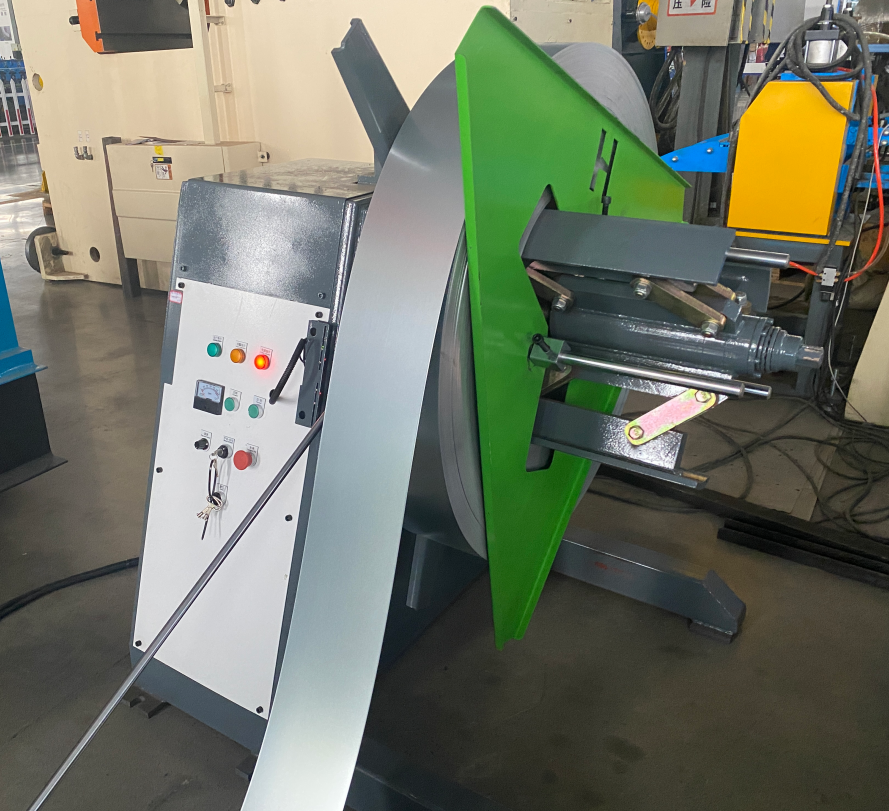

6 Tons auto hydraulic decoiler

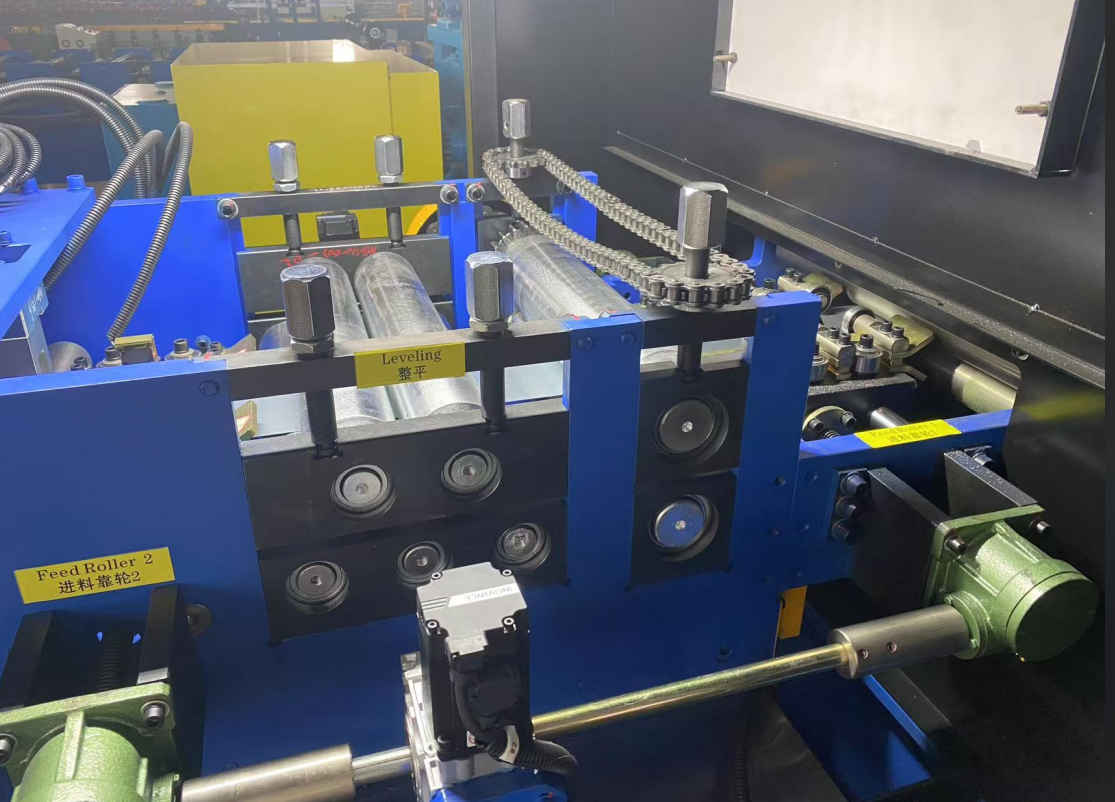

Feeding and Leveling Device

Punching device

Main rolling forming machine

Hydraulic cutting system

Online printer

Receiving table:4 meters

Punching device details:

1. Punching type: hydraulic punching,driven by servo motor

2. full automatic continuous punching die (pipe holes, web holes, small side cuts, fixing holes, chamfers, web necking, shearing, nail socket bolt holes, etc.); Punching precision within+/-1mm

3. There has 4 sets web notch molds and end truss molds in total

4. Sizes range no need change mold within 17mm, like

u 83mm-100mm

u 138mm-155mm

u 195mm-212mm

u 237mm-254mm

(the start of range can as your request)

the web notch mold and end truss mold need change the when the size changing more than 17mm

5. If you add other sizes of molds in the future, we can customize them for you(with good price)

Main rolling forming machine

1. Changing sizes: Full-automatic (change sizes automatically by PLC control, pressing button is compatible)

2. Transmission: chains with tension stabilization device

3. Drive: servo motor 22kw +arc bevel gear reducer

4. Roller material: Cr12,heat treat to HRC58-60 after CNC processing, and then finish turning, polishing and electroplating

5. Shaft material:40Cr, after CNC processing, HRC28-32 is quenched and tempered, and then polished and electroplated

6. Forming speed: High speed 30 m/min (depending on the number of punches and cutting length)

7. Forming station: 19 sets of spindle roll forming(5 stations forming lip;11 stations forming flange;3 stations for straight the keel

8. Frame structure: Arch type

9. Total weight of the machine: 8 tons;

10.Total machine length: 11.5m x 3.0m x 1.95m (length * width * height);

Hydraulic cutting system and computer system

Online printer

1. Printing is automatic control by PLC. it works automatic to print each profile for easy assembling according to the drawing. the text can be easy to input.

2. Customer can freely design the printer information.

3. Two sets of printers print the outside of both flanges

You are welcome to send us message to know more about the machines.

If you have any questions or need help: feel free to contact with our team.

+86 317 5670260

+86 15227520688

Add.:N0.4 ROAD, ECONOMIC DEVELOP ZONE, BOTOU COUNTY, CANGZHOU CITY, HEBEI PROVINCE, CHINA

NAVIGATION

RECRUIT DEALERS